A stay in Parma would most definitely NOT be complete without a visit to a certified Parmigiano Reggiano and Prosciutto di Parma Factory.

Similar to the way that the production of Champagne is very heavily regulated and controlled, so is the production of Parmigiano Reggiano cheese (parmesan cheese) and Prosciutto di Parma (Parma ham). These extremely natural products are produced exclusively in the Parma region and exported all over the world. They are renowned for their taste, quality and purity.

Matteo from ParmaLook Tours (hit them up for all types of cultural tours, not just food, if you’re in Parma) took me to see how they’re made. Here is what I learnt about the fascinating process of making Parmigiano Reggiano. Read about my learnings of Parma Ham here.

Parmigiano Reggiano

An overview

The entire process of making Parmigiano Reggiano cheese from the feeding and milking of the cows to the transport of the milk, factory specifications, ingredients and final stamp of approval (every single round of cheese is checked) is controlled by the Parmigiano Reggiano Consortium. They give their stamp of approval (literally) on every single piece of cheese.

The cows eat very specific grass from Parma region, the milk is not pasteurised and the only 5 ingredients are milk, natural rennet, fermented whey, salt and water.

Guard dog not doing a good job

The Tonelli family own the San Pier Damiani Factory have been making Parmigiano Reggiano cheese since the day of St Peter Damian in 1965 (hence the name of their factory). Today the family production is an intimate affair with just 4 people working every day (because the cow’s don’t stop giving milk) to produce an average of 10 cheeses (~40kg each) per day.

The Cows

Every morning and evening Mr Tonelli heads to the local dairy to collect the milk from the (morning and evening) milking of the Parma Friesian cows. The cows are fed a strict diet of a combination of fresh and dry foliage – a special grass specific to the Parma region.

The Tonelli truck used to pick up the milk from surrounding dairies every day.

The Milk

The milk is not pasteurised but lays in open vats at the Tonelli factory before being used for that day’s cheese production. The evening milk lays overnight to ferment a little and the cream is skimmed off in the morning. However the milk from the morning milking is mixed directly with the skimmed milk of the previous evening.

“Cooking” the Milk

The milk is divided into cauldrons where a small amount of rennet (an enzyme found in the stomach of the friesian cows) and fermented whey (from the previous day’s production) are added. The milk is then heated to 30 degrees celcius for 15 minutes.

“Cooking the milk”

After this heating, Mr. Tonelli does an action called “Spinature” where he mixes the milk, with what I describe as a giant whisk, while heating it to 55 degrees celsius. The milk never gets pasteurised (72 degrees celsius) because this would kill the bacteria and enzymes that are needed to make the cheese.

The Cheese Forms in the Cauldron

The milk is then allowed to rest for 40-50 minutes. The actions of the fermented whey (which contains lactic acid bacteria) and the enzymes cause proteins in the milk to coagulate at the bottom of the cauldron.

Lifting the cheese out of the bottom of the pot.

Using a wooden spatula, the large pile of cheese is lifted to the top of the cauldron and suspended with a ‘cheese cloth’ while the remaining water/whey mixture drains away. Each cauldron produces 2 large cheeses.

Draining the water

These cheeses are placed in a plastic mould and allowed to sit on a table in the factory for 1 day to allow water/whey to drain from them. It is then moved downstairs where a metal mould with a certified Parmigiano Reggiano imprint is placed on it. This imprint also has shows the date of production and manufacturer so the cheese can be traced. The cheese sits for another day.

Draining the cheese after coagulation.

The ‘water’ and whey left over is used by other areas of the food industry for other products. But a small amount is kept and left overnight to ferment to provide the fermentable bacteria for the following day’s cheeses.

Salt Bath

After 2 days of draining, the cheeses are stripped of their moulds and placed in a salt bath for about a month. The water of the salt bath is rarely changed (just topped up as needed when things spill-over etc.) and kept saturated with a constant supply of salt.

Cheeses in saturated salt bath.

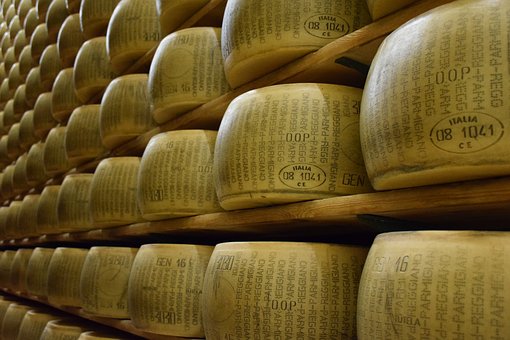

Aging

Then it’s time to age the cheese! In a temperature-controlled room on chestnut timber shelves, the cheese has a great time chilling-out for a year. The cheese naturally sweats due to the salt content and must be frequently brushed to remove oil and moisture.

Aging the cheese

Certification

After 12 months in the aging room, officials from the Parmigiano Reggianno Consortium come to the factory and check every single cheese for quality. The tests involve knocking and listening for a distinct sound, smelling and occasionally tasting. If the cheese is of the right quality, it will be given the official and final Parmigiano Reggiano stamp. Occasionally the certifiers will allow a “second class” of Parmigiano Reggiano cheese to be stamped but to distinguish from the official class, these cheeses are scored with lines around the outside.

Official Parmigiano Reggiano mould used to imprint certified markings in the cheese.

Cheeses that do not meet quality of either class are stripped of the original imprint and sold as ‘regular cheese’.

While the cheese is stamped after 12 months. It is most common to allow the cheese to age for 2 years and even longer in some cases before eating. The aging process increases the cheese’s hardness, enhances its flavour and saltiness. When you buy Parmigiano Reggiano cheese in a Fromagerie you can usually choose between cheeses aged anywhere from 12-40 months.

This process is the same for all Parmigiano Reggiano cheeses produced by the 353 factories in the region.

You can eat the end of your Parmigiano Reggiano!

Unlike cheese encapsulated in wax, Parma cheese is ALL CHEESE. With the aging process, the outer edges get dry and hard to eat. Matteo suggested his favourite way to eat them is to grill them. I popped them in the oven and they crisped up beautifully to make crunchy-parmesan flavoured pieces for salads! There are heaps of other ways to use them too, read about the possibilities of parmesan crusts here.

So that’s what I’ve learned about making Parma cheese! And cheese-making in general! Pretty cool hey! I’m looking forward to attempting some home-scale cheese at when I get back to Australia :).

Matteo has Parmigiano cheese making in his blood and is a local to the region. His tours are full of fun stories and loads of detail. There was not one question I asked that he didn’t know the answer to! I highly recommend taking a tour with him – check out all the available tours on his ParmaLook website!